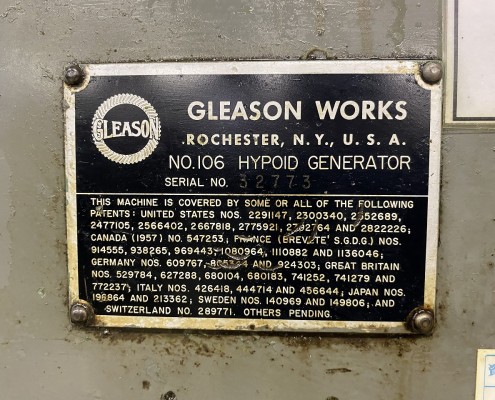

Gleason #106 – Hypoid Gear Generator

Specification

Cone Distance, maximum

0 To 35-Degrees Spiral Angle

7.5″ Cutter 1.25″ Face…………….. 4.25″/(108mm)

Pitch Diameter, Maximum (90-Degree Shaft Angle)

O To 35-Degree Spiral Angle

Ratio 10:1……………………….. 8.5″/(215mm)

Ratio 2:1………………………… 7.5″/(190mm)

Ratio 1:1………………………… 6″/(152mm)

Maximum Face Width………………… 1.25″/(32mm)

Diametral Pitch Maximum……………. 4 D.P./(6.3 Module)

Maximum Full Depth………………… .500″/(126mm)

(May Be Improved w/Special Cutters)

Displacement Of Cutter Zxis From Cradle

Axis…………………………….. 0 To 6″/(0-152mm)

Root Angle Setting………………… – 12 To 90 Degs

Index Range………………………. 5 To 97 Teeth

Cutter Diameters Utilized………….. 1.5,2,3.5,4.5,6,7.5″

(38.1,50.8,88.9,101.6,152.4,190.5mm)

Workhead Offset, Above/Below Center…. 3″/(75mm)

Sliding Base Adjustment:

Advance From Machine Centerline…….. 2″/(51mm)

Withdraw From Machine Centerline……. 3″/(75mm)

Distance Work Spindle Nose To

Machine Centerline………………… 1.25″-9″/(32-228mm)

Wk Spdl Taper Hole Dia. (Lg End)……. 3-29/32″

Wk Spdl Taper Hole Dia. (Lg End)……. (99mm)

Spindle Taper Per Ft………………. 39/64″/(1:18.5mm)

Depth Of Taper……………………. 6″/(152mm)

Diameter Of Spindle Thru-Hole………. 2-7/16″/(62mm)

Feed (Seconds Per Tooth)…………… 4.9 To 68.6

Cutter Speeds Ft./Min……………… 74-380/(25-133)

Main Motor Horsepower……………… 5 HP/1800 RPM

Coolant Pump Motor………………… 5 HP/3600 RPM

Hydraulic Pump Motor………………. .75 HP/1800 RPM

Floor Space Required………………. 61.25x 84.25″

Floor Space Required………………. (1556x2140mm)

Machine Approx Net Weight………….. 14,300 Lbs.

Machine Approx Net Weight………….. (6,500 kGs)