- MAXIMUM DIAMETER OF GEAR 18″

- MAXIMUM OFFSET C/L OF GEAR SPINDLE ABOVE OR BELOW C/L OF PINION SPINDLE 3.5″

- DISTANCE FROM CENTER OF GEAR SPINDLE TO NOSE OF PINION SPINDLE, MAX. 12″, MIN. 5.75″

- DISTANCE FROM CENTER OF PINION SPINDLE TO NOSE OF GEAR SPINDLE, MAX. 6.375″, MIN. 3.50″

- BRAKE (GEAR) SPINDLE (#14 TAPER):

DIAMETER OF TAPER HOLE AT LARGE END 2-19/64″

TAPER PER FOOT 1/2″ - DRIVE (PINION) SPINDLE (#39 TAPER):

DIAMETER OF TAPER HOLE AT LARGE END 3-39/32″

TAPER PER FOOT 39/64″ - DRIVE SPINDLE SPEED 1200 RPM

- FLOOR SPACE (APPROX.) 73″L X 60″W X 66″H

- WEIGHT APPROX. 5,800 LBS.

글

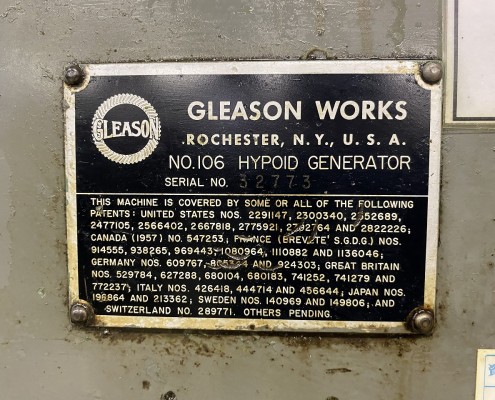

Gleason #106 – Hypoid Gear Generator

/in BEVEL GEAR, featured post, GLEASON /by ilshincoGleason #106 – Hypoid Gear Generator

Specification

Cone Distance, maximum

0 To 35-Degrees Spiral Angle

7.5″ Cutter 1.25″ Face…………….. 4.25″/(108mm)

Pitch Diameter, Maximum (90-Degree Shaft Angle)

O To 35-Degree Spiral Angle

Ratio 10:1……………………….. 8.5″/(215mm)

Ratio 2:1………………………… 7.5″/(190mm)

Ratio 1:1………………………… 6″/(152mm)

Maximum Face Width………………… 1.25″/(32mm)

Diametral Pitch Maximum……………. 4 D.P./(6.3 Module)

Maximum Full Depth………………… .500″/(126mm)

(May Be Improved w/Special Cutters)

Displacement Of Cutter Zxis From Cradle

Axis…………………………….. 0 To 6″/(0-152mm)

Root Angle Setting………………… – 12 To 90 Degs

Index Range………………………. 5 To 97 Teeth

Cutter Diameters Utilized………….. 1.5,2,3.5,4.5,6,7.5″

(38.1,50.8,88.9,101.6,152.4,190.5mm)

Workhead Offset, Above/Below Center…. 3″/(75mm)

Sliding Base Adjustment:

Advance From Machine Centerline…….. 2″/(51mm)

Withdraw From Machine Centerline……. 3″/(75mm)

Distance Work Spindle Nose To

Machine Centerline………………… 1.25″-9″/(32-228mm)

Wk Spdl Taper Hole Dia. (Lg End)……. 3-29/32″

Wk Spdl Taper Hole Dia. (Lg End)……. (99mm)

Spindle Taper Per Ft………………. 39/64″/(1:18.5mm)

Depth Of Taper……………………. 6″/(152mm)

Diameter Of Spindle Thru-Hole………. 2-7/16″/(62mm)

Feed (Seconds Per Tooth)…………… 4.9 To 68.6

Cutter Speeds Ft./Min……………… 74-380/(25-133)

Main Motor Horsepower……………… 5 HP/1800 RPM

Coolant Pump Motor………………… 5 HP/3600 RPM

Hydraulic Pump Motor………………. .75 HP/1800 RPM

Floor Space Required………………. 61.25x 84.25″

Floor Space Required………………. (1556x2140mm)

Machine Approx Net Weight………….. 14,300 Lbs.

Machine Approx Net Weight………….. (6,500 kGs)

GLEASON #116 – HYPOID ROUGHER

/in BEVEL GEAR, GLEASON /by ilshincoGLEASON #116 – HYPOID ROUGHER

Specification

- CAPACITY

Max cone distance (30 degree angle and 300 mm cutter): 228 m

Max extreme ratio: 10 to 1

Max gear pitch diameter (30 degree spiral angle):

-Ratio 10 to 1: 457 mm

-Ratio 2 to 1: 406 mm

-Ratio 1 to 1: 323 mm

Diametral pitch (coarsest): 12,7 mod.

Max full depth: 25,4 mm

Max face width: 69,9 mm

Number of teeth: 5 to 150

- WORK SPINDLE

Diameter of taper hole at large end: 100 mm

Taper per foot: 39/1600 mm

Depth of taper: 150 mm

Diameter of spindle nose: 137,5 mm

- CUTTER DIAMETER

Diameter: 125 mm; 150 mm; 187,5 mm; 225 mm; 300 mm

- WORKHEAD SETTINGS:

Max offset above center: 112,5 mm

Max offset bellow center: 112,5 mm

Distance from machine center to nose of spindle:

-Max: 337,5 mm

-Min: 62,5 mm

SPEEDS AND FEEDS

Cutter speeds: 20 to 115 rpm

Feed (seconds per tooth): 9 to 80 seconds

ELECTRICAL EQUIPMENT

Voltage: 380 V, 50 Hz

Feed motor: 5,5 kW

Hydraulic motor: 3 kW

Coolant motor: 1,5 kW

MISCELLANEOUS

Floor space: 2560×1980 mm

Height: 1620 mm

Net weight: 10977 kg

Shipping weight (boxed for export): 11930 kg

Size of case: 3040x2760x1950 mm

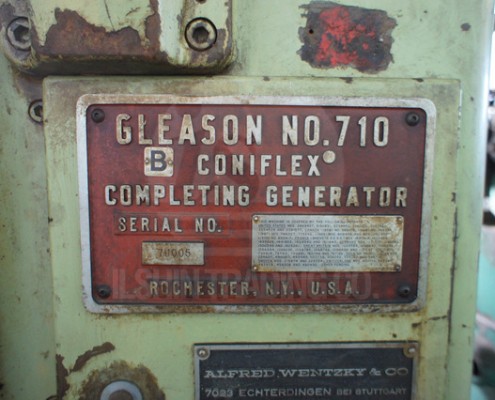

GLEASON #104 – CONIFLEX CUTTER SHARPENER

/in BEVEL GEAR, GLEASON /by ilshincoGLEASON #104 – CONIFLEX CUTTER SHARPENER

Specification

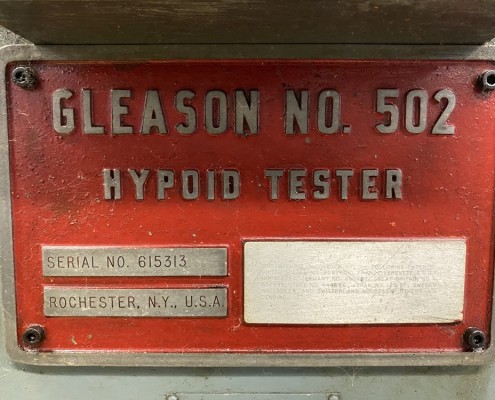

Gleason #17 – Hypoid Gear Tester

/in BEVEL GEAR, GLEASON /by ilshincoGleason #17 – Hypoid Gear Tester

Specification

Gleason #528 – Cutter Inspection Machine

/in BEVEL GEAR, GLEASON /by ilshincoGleason #528 – Cutter Inspection Machine

Specification

- Conventional Spiral Cutters (standard): 3.5″ – 19.7″

- Coniflex Cutters: 15″ (inserted blade)

- Revacycle Cutters: 16″ – 25″

- Floor Space: 31″ x 38″

- Height: 59″

- Net Weight: 1,900 lbs

- Shipping Weight (Boxed for Export): 2,500 lbs

- Size of Case: 48″ x 43″ x 69″

일신무역상사

TEL (++82)-41-569-2588

FAX (++82)-41-568-2788

E-MAIL ilshinco@paran.com

OFFICE

충남 천안시 서북구 성거읍 석문길 311 (문덕리 155-2)

311, Seongmun-gil, Seonggeo-eup, Seobuk-gu, Cheonan-si, Chungcheongnam-do, Korea